Global energy transition has transformed demand for many commodities, especially for battery raw minerals such as nickel, with primary nickel demand from the battery sector estimated to grow from 571kt in 2023 to 1,252kt by 2027. Indonesia has the world’s largest nickel laterite reserves and is the single most important source of supply to meet the growing demand. In particular, Indonesian NPI producers are starting to convert some of their production into matte, which can be further converted into nickel sulphate and used as one of the main raw materials for precursor cathode active materials.

Author Victor Chin

Principal Consultant View profile

Author Danwu Chen

Senior Consultant View profile

Author Ruiming Zhang

Research Analyst View profile

Indonesia is also in discussion with the US on a potential limited free trade agreement which will allow some minerals including nickel to be shipped to the US and qualify for EV tax credits under the Inflation Reduction Act (IRA). However, the NPI production process (RKEF) is relatively emission-intensive compared to other production routes, and it raises questions as to whether Indonesia has high enough environmental standards to be an IRA-compliant supplier.

Nickel processing is emission intensive, especially for NPI

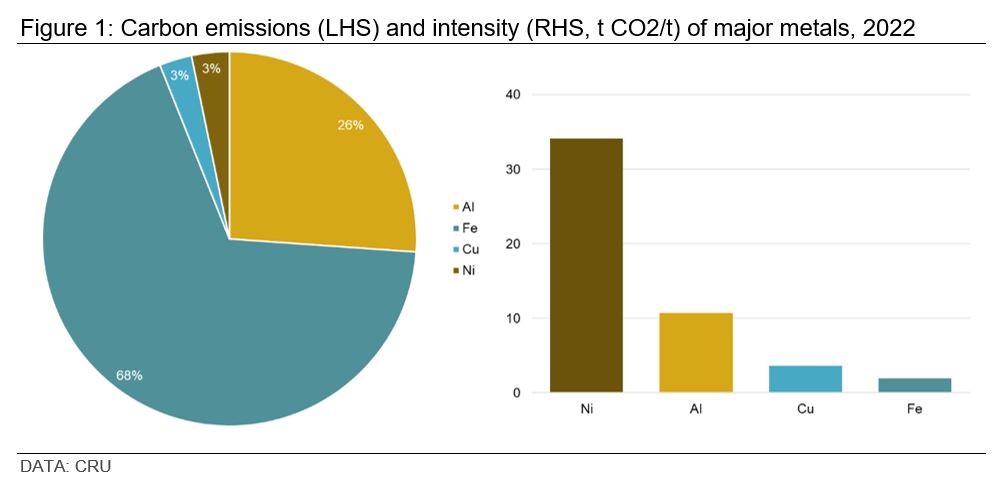

Generally, total carbon emissions from the nickel value chain (including mining, smelting, refining and further processing of nickel) are relatively low compared to other major metals such as steel, copper and aluminium. Emissions from nickel only account for less than 3% of total major metals production emission in 2022 globally.

However, the emission intensity on a per tonne nickel basis is comparatively high and its carbon emission intensity is 16x higher than steel on average.

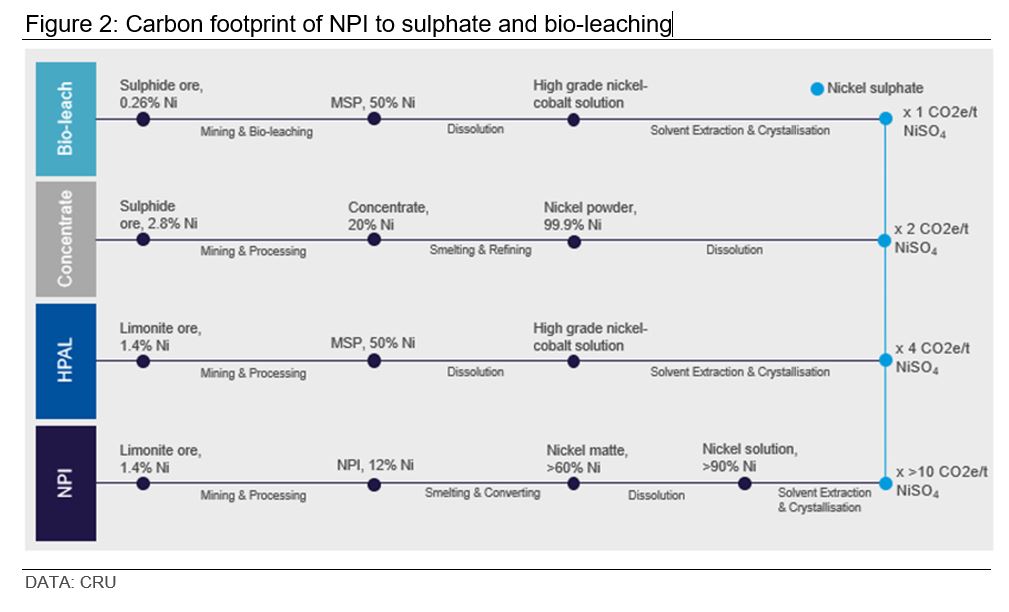

While the carbon emission intensity varies across the production of different nickel products. Pyrometallurgy requires high energy and heat to convert the low-grade nickel ore to the 12% NPI product.

As a result, NPI has the highest emission intensity compared to other nickel production route, and further processing to convert NPI into nickel sulphate makes the total carbon emissions (scope 1&2) to be about 20x higher than those of bio-leaching origin nickel sulphate.

How much less emission could NPI achieve?

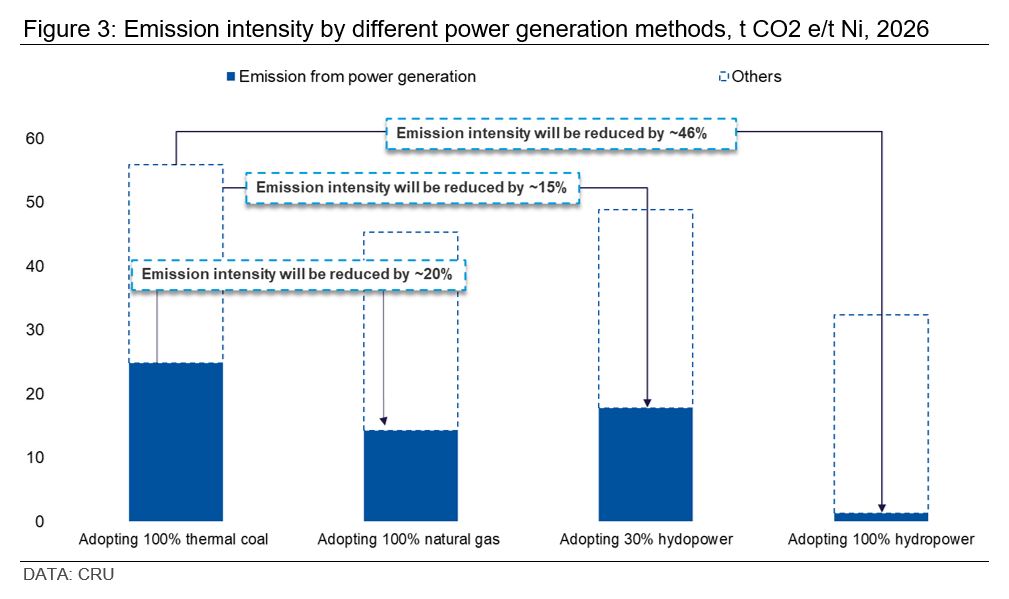

Power generation currently accounts for almost half of the total emission for NPI production in Indonesia due to the consumption of coal. The adoption of renewable or natural gas would reduce carbon emission significantly.

By adopting natural gas or hydropower for power generation, we estimate that carbon emission can be reduced by 20% to 45% compared to coal power generation. However, production cost is estimated to increase by 10 to 30% by adopting natural gas or hydropower as the primary energy source.

If Indonesia NPI producers would like to supply to the growing demand from the US EV battery value chain, environmental issues such as carbon emission will be too significant to ignore, and it may encourage some NPI plants to replace coal power with a cleaner energy source.

Explore this topic with CRU

Author Victor Chin

Principal Consultant View profile

Author Danwu Chen

Senior Consultant View profile

Author Ruiming Zhang

Research Analyst View profileThe Latest from CRU

Decarbonisation will reshape global steel trade flow

CRU’s Steel Long Term Market Outlook presents comprehensive analysis of global steel trade flows until 2050. Decarbonisation will play a significant role in redefining...