Contributor Ian Warden

Senior Analyst, Steel View profile

Blast Furnace emissions can be cut, but where and how?

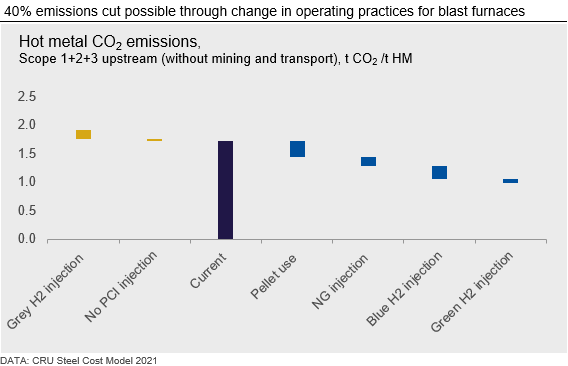

Under pressure to decarbonise from policymakers and other stakeholders, BF operators around the world are seeking to reduce emissions. This has led them to think about how they can change their operating practices to reduce emissions from their existing steel works without losing their competitiveness.

There are a number of options to make substantial emission cuts from BFs in operation today. Two of the most powerful options are considered in this analysis:

- Improving ferrous burden quality by substituting sinter with pellet.

- Changing reductants injected to the BF via the tuyeres. Non-renewable PCI is most widespread. Three leading alternatives for emission reduction are:

- Natural gas

- Blue H2 and

- Green H2

As part of our research into the marginal abatement costs of carbon in the steel industry, we have used CRU’s Steel Cost Model to estimate how far carbon prices need to increase to incentivise widespread global uptake of each of these abatement practices.

40% emissions cut possible through change in operating practices for blast furnaces

Explore this topic with CRU

Contributor Ian Warden

Senior Analyst, Steel View profile