Author Erik Heimlich

Head of Copper & Zinc View profile

Author Marta Dec

Head of Base Metals Costs & Emissions, Principal Analyst View profile

Author Charlie Durant

Research Manager View profile

This year has seen Environmental, Social and Governance (ESG) issues rise to the top of the agenda for the base metals industry. Last year was one of the warmest years on record, with global temperature at 1.2 degrees above the pre-industrial baseline. Action must be taken soon to stop or mitigate further consequences of climate change. The focus on ESG is growing rapidly, the need for action is bringing with it threats and opportunities across the base metals sector.

Emissions in focus for copper and nickel miners

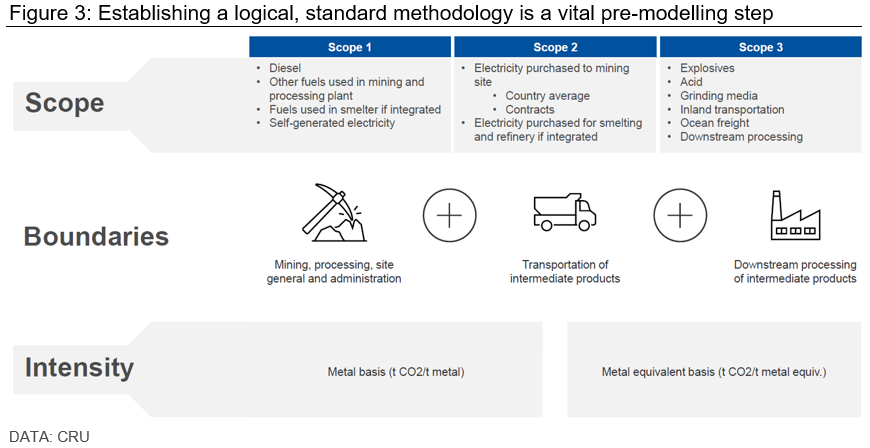

CRU has put considerable resource into developing an Emissions Analysis Tool, which allows users to compare emissions on a mine-by-mine basis. We believe that understanding emissions, and being able to measure and compare them, is a key requirement before the industry can start to effectively address them.

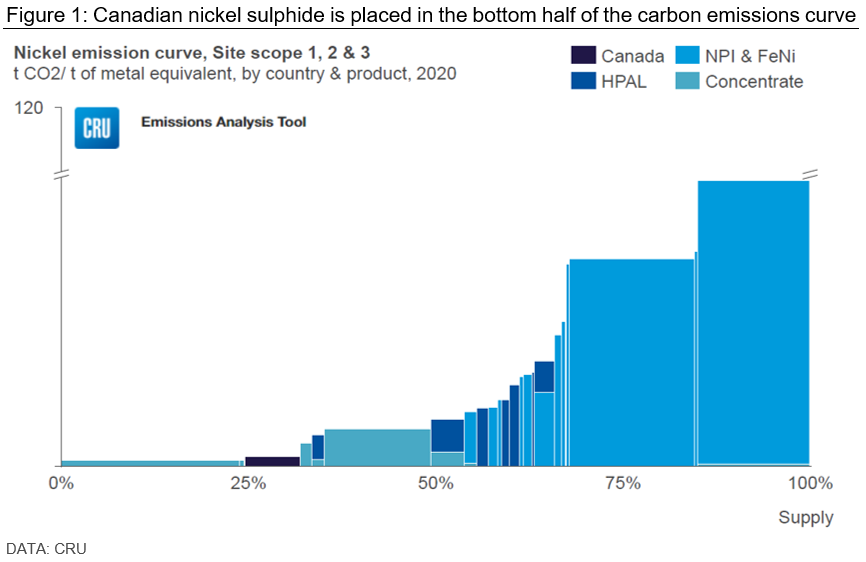

Below we show an emissions curve for nickel, highlighting differences by processing route and country. The chart is based on CO2 emissions per tonne of metal equivalent for nickel. To highlight what can be achieved with harmonised information, we have also detailed the Canadian nickel sector.

Canada, taken as a whole, sits in the 2nd quartile. It produces only concentrate type material. Canada benefits from having a large portion of nickel produced from underground mines, which use renewable power from the country’s energy grid. However, if we dive deeper into the numbers, several remote assets still use fossil fuels for self-generated power. Greater use of renewables could further lower Canada’s position on CRU’s Emissions Curve.

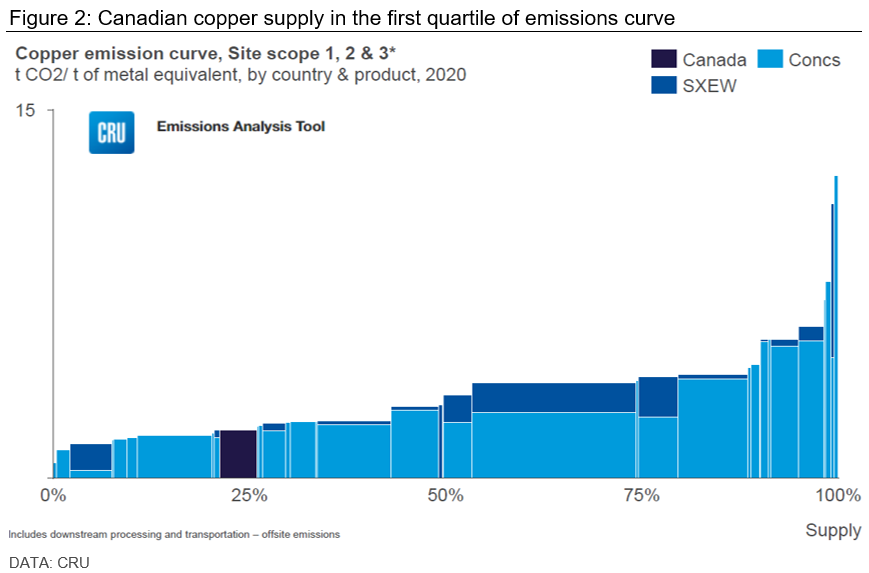

Compared to nickel, modelling emissions in the copper industry is simpler in terms of producing routes. Copper is processed either via concentrates and pyrometallurgical processing, or to a lesser extent via SXEW / hydrometallurgical processing. SXEW can be more intensive in terms of carbon emissions given that electrowinning is a very energy intensive process. But, compared to nickel, there is a lower degree of variation among the different copper mining countries.

Half of copper’s total emissions are defined as Scope 1 and one third of total emissions are generated from diesel consumption. Diesel, used by mobile and stationary equipment, is one of the most important contributors to emissions at open cast mines. This could become a key focus for Canadian mines, where we may see increased electrification on site. However, this ultimately means that investment is needed. The partial or complete electrification of equipment, for example trolley assist or electric vehicles, has the potential to help significantly reduce emissions at mine site. Of course, electrification is most effective at reducing emissions when renewable energy is used.

If we look at the CRU Copper Mine Emissions Curve, the bottom two quartiles are comprised of mines that have three times lower CO2 per kWh of supplied energy than the mines sitting in the top half of the curve. This is partly the result of the uneven distribution and availability of renewables. The bottom 30% of the curve consists of emissions from assets with medium to high availability of renewable power.

Emissions curves are crucial in addressing which strategies can be adopted in the path to net zero. The capital required to lower emissions will clearly increase for both projects and existing operations. However, there will be constraints in terms of geographic location and the process flow sheet. Canadian copper and nickel miners have already been active in working towards lower emissions, but significantly more investment is still needed.

Globally, we see carbon offsets gaining ground to improve the carbon footprint of a number of companies, especially in cases where there are fewer options available for significant emissions reduction. However, emissions remain only one of the ESG challenges that the base metals sector faces.

Electrification and automation becoming cheaper

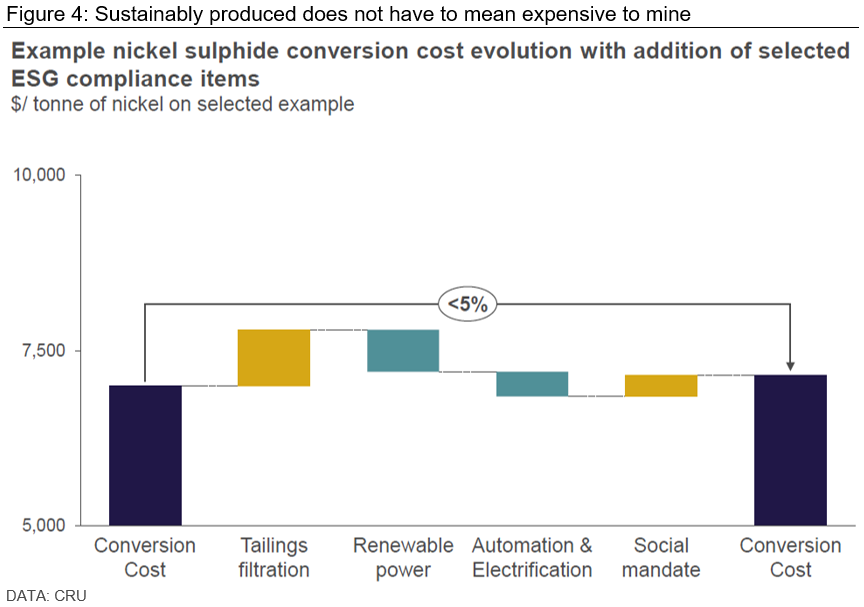

The costs of electrification and automation are falling each year, with OEMs and producers working closely together. Underground mines already include a vast amount of autonomous and fully electric machines, including electric jumbos, loaders, and trucks. Increased automation, the spread of optimisation, and the greater focus on ESG does not always mean mining at much higher costs.

Glencore’s Onaping Depth nickel underground project is making use of battery electric vehicles (BEVs), electric smart-ventilation, and all electric equipment to drill, blast and load. The use of electric vehicles has resulted in a 44% reduction in GHG emissions and a 30% saving for cooling equipment, which is extremely important for very deep mines facing a high geothermal gradient. Vale are operating around 20 electric machines in Ontario including personnel haulers, loaders, and trucks. They are aiming to double this in the next couple of years. Comparing nickel sulphide projects in Canada from 2012 to now, we have seen around a 20% increase in capital expenditure, as most now include strong environmental protection levers and foundations.

In copper and nickel mining, operating costs can, in part, be viewed as an opportunity. However, it depends on how much a producer invests upfront. Some opportunities are relatively simple to address, for example renewable power, which can come at a lower cost than fossil fuels. Automation often increases safety. Technologies like fatigue management have already significantly improved working conditions across the globe. New processes or changes to existing flow sheets could result in new by-product streams. However, there are some strategies which will inevitably cost more. Use of dry stacking in tailings increases operating costs. This is because of power usage for the filtration plant, higher maintenance cost of a new flowsheet, and the cost of hauling or transporting the tailings to the stack.

Meanwhile, trolley assist requires changes at mine sites. The permanent haul roads must be of a very good quality. There is also a need for skilled blasting and effective cable handling. Moreover, mine maintenance departments must be equipped to deal with technology changes and challenges, such as electric breakdowns or mine power outages. Emission reductions can also be achieved through efficiency gains, by increasing the speed of haulage and reduced wear and tear on equipment.

Tailings management remains a complex issue

Tailings management and disposal has been gaining increased focus. Miners will need to increase the use of advanced monitoring techniques, incorporating global standards and turning towards the best technology possible for tailings disposal.

Deep sea tailings disposal no longer seems to be a realistic option for Indonesian nickel projects. As such, miners are looking at dry stacking or filtered tailings. A filtration plant to de-water wet and fine tailings is a costly solution for an HPAL operation. Yet, over the LOM, the high capex can be partially offset against lower costs of closure or by limiting sustaining capital costs if lifts are not required.

By using new or advanced technologies, like the DNi process, one could filter the magnesium and iron at the pre-tailings stage, producing a saleable hematite product. This could be very important as iron can form a significant part of the tailings.

Tailings in sulphide operations are no less important. Canadian miners can proceed with conventional slurry tailings, but they still must ensure the right design is used, the monitoring is performed, and no harm policy applies. Developments are ongoing, and companies like FPX Nickel or Giga Metals are active in the space of researching nickel tailing’s ability to absorb carbon dioxide.

Concerns surrounding water availability and tailings, as well as increasing local community expectations, are growing. Many ESG issues are interrelated, with water, ore processing and tailings management a good example. In copper, declining ore grades mean that more material will need to be moved for every tonne of copper produced and tailings management could become more problematic.

A way of drastically reducing water consumption is tailings filtration and dry-stacking. For instance, Hudbay Minerals’ Rosemont open pit project in Arizona, is looking to overcome its long-standing permitting issue by using this option. This sort of development can also be taken up by underground miners, and support improvements in ore extraction. The Cozamin mine, operated by Capstone Mining in Mexico, is planning to use half of the filtered tailings to form a cemented paste backfill. This approach means not only less water consumption and smaller surface footprint, but also improvements in the underground ore extraction by enhancing underground pillar recovery.

In concentrate processing, we expect initiatives such as coarser particle flotation technologies, that can increase recovery and thereby decrease consumption of power and water consumption per unit of metal output. This is being advanced by Capstone at their Pinto Valley operation in the US. There have also been some interesting developments surrounding SXEW production as well, detailed in a recent CRU Insight. Copper Monitor subscribers can access it here: https://cruonline.crugroup.com/copper/cost/analysis/sxew-production-gets-a-second-chance/.

Water scarcity a growing concern for base metals miners

Management of water risks is a key component of mining activity, and its importance is only going to grow. The risks are varied, from flood risks to water quality risks, from ecological risks to water scarcity risks.

Stricter regulations in Chile remain a threat, and legalisation around glaciers protection, and potentially the periglacial and permafrost areas close to the glaciers, are under review. Depending on the extent of protection that is finally enforced, there could be a significant impact on existing operations and particularly on project developments.

Water scarcity has already caused disruption to operations. Moreover, conflicts related to competition for water resources have left mining assets stranded, with some mining projects being cancelled, and serious conflict erupting, in some cases severely damaging the reputation of companies. For copper, Central Chile is experiencing the worst drought in 60 years, with production at Anglo American’s Los Bronces the most affected large mine. Other large mines in the region, such as Antofagasta Minerals’ Los Pelambres, Codelco’s Andina, and Codelco’s El Teniente have all also faced significant challenges.

Around 10% of nickel production, 20% of zinc mining and 40% of copper mining occur in regions in high and extremely-high water-stressed regions. High water stress refers to a ratio of water demand to water supply of 40% or greater. In Chile, 80% of copper production is in extremely high water-stressed and arid areas. Regions where water scarcity is an issue include the US, Mexico and Australia (Cobar, Northparkes, Cadia). Due to climate change, water scarcity will become a more pronounced issue.

In terms of solutions, the first step has been to increase water use efficiency through higher recirculation rates and by eliminating avoidable losses, through evaporation for example. But this will not always be sufficient.

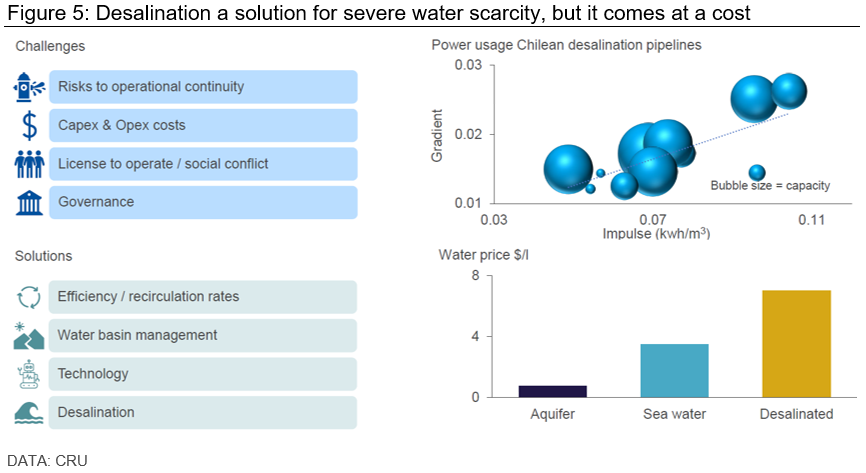

Chile’s copper industry is increasingly looking to desalination as a way of reducing the use of inland water supplies, yet this is no universal panacea. Seawater desalination plants and pipelines are also likely to grow in importance. Companies such as Teck Resources and Lundin Mining are taking water from the coast, processing it, and pumping it to high altitude. This only reinforces the need for offsetting costs, at least in part, with more water recirculation and quality improvement initiatives, as well as the need for more exposure to cheaper renewable energy.

Desalination requires significant amounts of power, as does pumping the water for extended distances and elevations. In Chile, desalination currently represents around 7% of power use by the mining industry and that is expected to increase to more than 10% in two decades. Renewable power will become even more important for miners who want to keep emissions in check. Chile will likely introduce specific rules for the treatment and disposal of brine which could potentially create operational issues.

Depending on the severity of water scarcity and the approach taken to deal with the challenge, the impact on capital and operating costs will vary significantly. Capital expenditure requirements can be large, whereas in the case of operating costs, there are increases, but savings are also possible.

Escondida has spent $4.3 bn on three separate desalination plants and pipelines. Teck’s QB2 project is building a $449 m desalination plant, while Antofagasta Minerals is building a $520 m plant. In terms of operating costs, desalinated water in Chile can be eight times more expensive than that from a local aquifer.

Huge investment needed to meet ESG requirements

ESG concerns bring both opportunities and threats. Ignoring these issues is no longer an option. For the base metals industry to progress along the path towards net zero, vast investments are needed from miners, OEMs and from the downstream sector.

Concerns around water availability and possible pollution from discharges, particularly tailings, together with increasing community expectations, will drive the capital intensity of new projects up and likely extend the time between exploration and commercial production.

Yet, while the threats are many, there are also opportunities. More can be done with existing technologies, which have yet to see their use peak. There are opportunities for lower operating costs, due to increased automation, electrification, and cheaper, greener energy. ESG will create winners and losers, and leaders and laggards in the base metals sector. Strategic thinking and bold decision making are therefore needed.

Interested in the seminar presentations or related analysis, prices and forecasts?

Request more information about the analysis, prices, forecasts and presentations - our team will be in touch to find out how we can help you.

Get in touch with our team

Explore this topic with CRU

Author Erik Heimlich

Head of Copper & Zinc View profile

Author Marta Dec

Head of Base Metals Costs & Emissions, Principal Analyst View profile

Author Charlie Durant

Research Manager View profile