China drives demand again

Covid-19-related disruptions hit refined demand harder than supply across the base metals complex in 2020. First China, then the rest of the world imposed lockdowns to try to control the spread of the virus. China’s rapid, stimulus-driven demand recovery from 2020 Q2, after a strict lockdown and severe demand losses in the first quarter, played out across the metals. Industrial demand in Europe, North America and parts of Asia plummeted due to lockdowns and supply chain issues.

For zinc, copper, and nickel we now expect that the Chinese stimulus will result in more than simply a return to the previous growth pattern. Our demand forecasts for China through 2020-2025 are now higher than our pre-pandemic forecast. For zinc, pre-pandemic, we were beginning to question whether China had reached peak zinc demand, given a small contraction in 2018 and only marginal growth in 2019.

In the world excluding China, the picture is less positive. We do not expect all regions to see last year’s losses fully recovered this year. Covid-19 remains the key risk in the short term, with developing countries still struggling to cope with the virus.

To the upside, further metals-intensive stimulus policies could be introduced. For copper and nickel, there is the potential that the positive impact of the green revolution is felt sooner rather than later. However, we should remember that green energy accounted for less than 5% of global copper demand in 2020. Zinc is not expected to benefit from a significant surge in demand as part of the green revolution.

Renewables will help drive copper, supportive for zinc

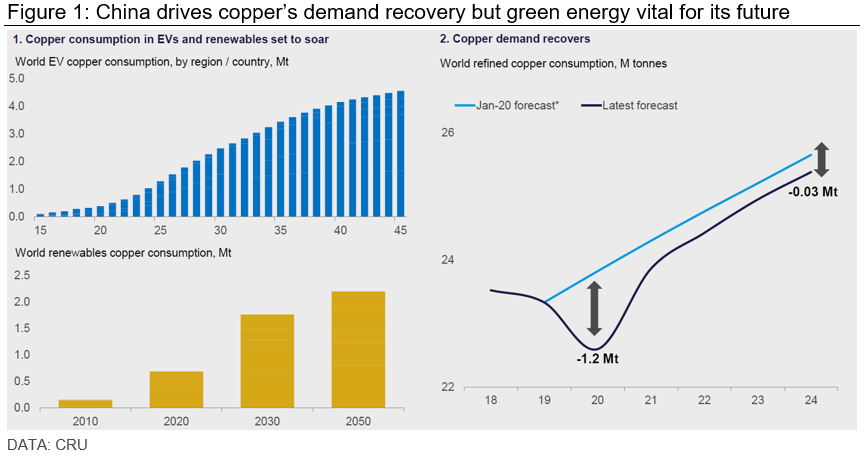

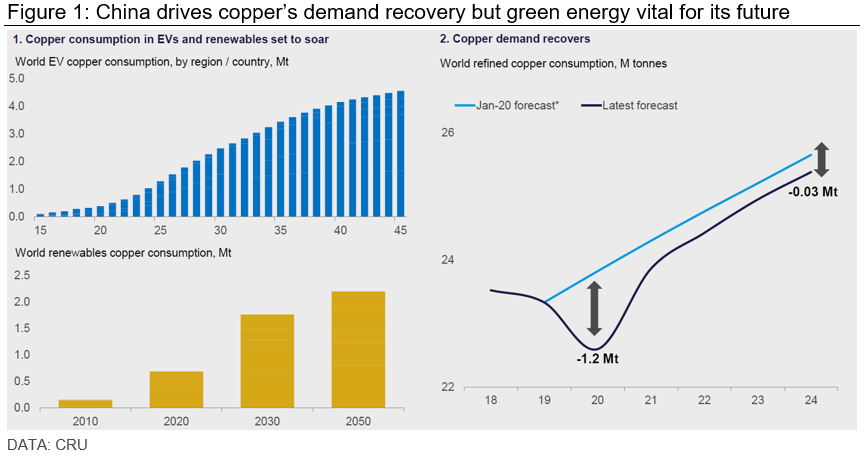

If the world is to even approach the widely stated aim of net zero emissions by 2050, then there will need to be a wholesale shift away from hydro-carbon based power generation towards clean energy sources. For copper renewable energy, primarily wind and solar, and electric vehicles, along with the upgrades and new electricity infrastructure needed to support them will help power demand. We expect global copper consumption from renewables to increase from 700,000 t/y in 2020 to 1.8 Mt/y in 2030.

Renewable energy will play an important role in supporting zinc demand in the coming years. Offshore energy is one of the more zinc-intensive renewable energy sectors and is set to grow rapidly in the coming decades, although from a small base. Solar arrays are often mounted on galvanised steel frames and can cover vast areas. Solar is therefore expected to account for an increasing portion of refined zinc demand going forward. Zinc utility-scale batteries are a small but potentially fast-growing sector and will add to overall renewables-related zinc demand. However, for zinc the green revolution is not game-changer.

Electric vehicle market at inflexion point

Last year appears to have been something of an inflexion point for the electric vehicle industry. European sales of electric plugins smashed through the 1 M unit barrier, and in doing so the region overtook China as the world’s largest EV market, albeit thanks to some extremely generous subsidies and tax breaks.

The interest in electric vehicles for copper is because metal intensity of use at around 80kg per vehicle, is up to four times that for a standard internal combustion engine. Including mild hybrid vehicles and charging infrastructure, global EV-related copper demand is forecast to increase from around 300,000 t in 2020 to over 4 Mt in 2040.

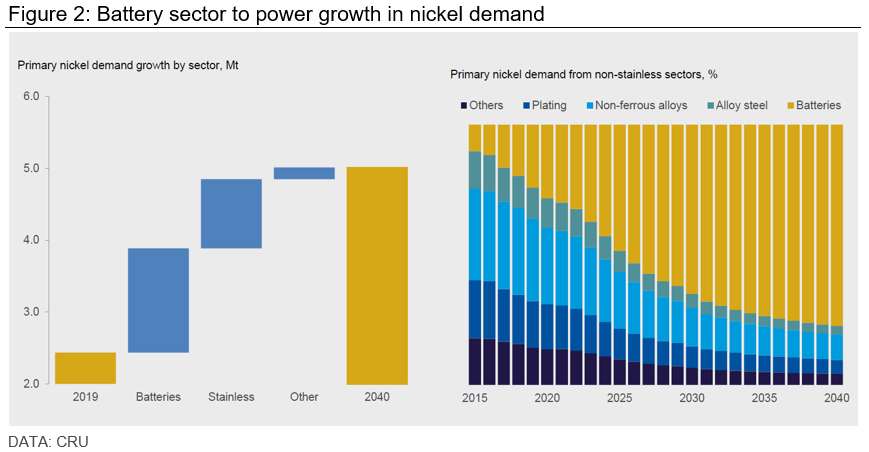

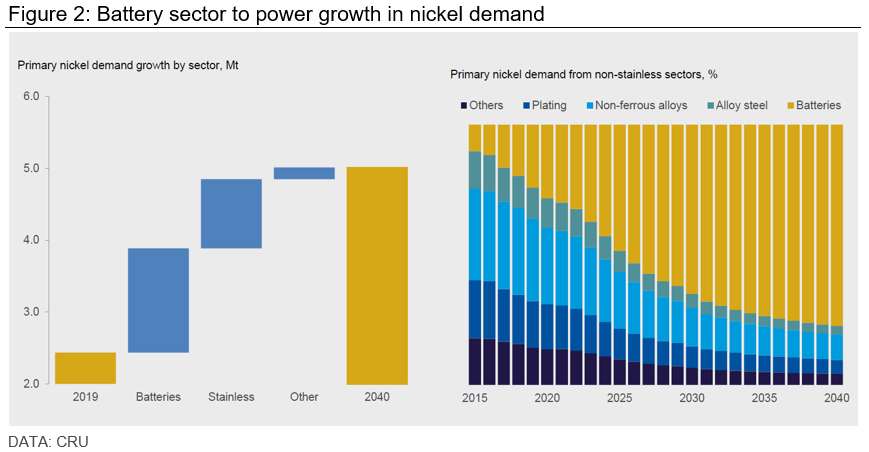

Nickel is used in a wide variety of applications other than stainless steel, which together account for around one third of global nickel demand. The main growth within the non-stainless area is expected to come from the battery sector on the back of increasing penetration of electric vehicles in the automotive sector, using nickel intensive batteries. We forecast the battery sector will represent almost 60% of nickel demand growth out to 2040.

Substitution a threat for copper and zinc

Zinc is not generally considered to be an EV technology metal. While the auto sector will remain an important zinc consumer, the trend towards light-weighting of vehicles, which began as automakers tried to meet stricter emissions regulations, will continue as they aim to maximise EV battery performance. While substitution of galvanised steel for aluminium auto sheet is still confined mostly to high-end vehicles, the trend will continue to chip away at auto-related zinc demand.

I

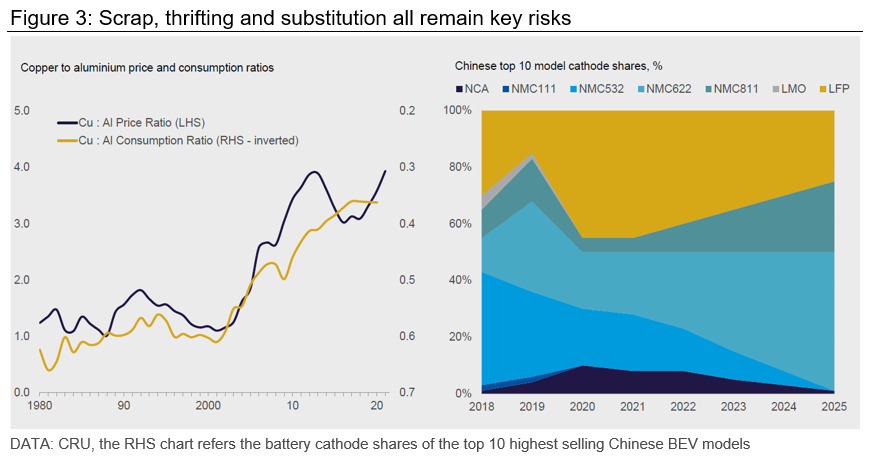

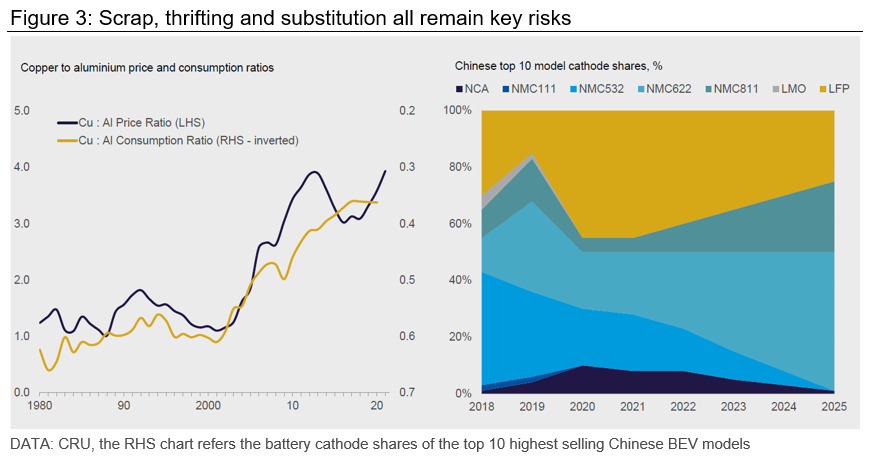

For copper there remains the threat of substitution, especially to aluminium. Forty years ago prices were similar, where they remained up until the turn of the millennium. Since then price ratios have risen to as much as four in the period following the GFC and again over the last year. Since 2000, the primary aluminium market has grown from 15 Mt to almost 65 Mt, whereas the refined copper market has only increased from 10 Mt to 23 Mt.

Looking at potential substitution in renewables, the lowest threat appears to be in offshore wind. There is a greater threat, especially of MV power cable, in solar and onshore wind, where maintenance can be undertaken more frequently.

In the case of electric vehicles, aluminium scores highly not only in terms of cost but also because of potential weight savings. However, the fact that its cross sectional area needs to be over 50% greater than that for copper for the same level of conductivity in particular, limits areas for potential substitution.

Technology change could alter intensity of use

We still expect NMC to cement its position as the “industry standard” battery chemistry in the EV sector. However, non-nickel-based battery chemistries are typically cheaper and safer, but at a cost of much lower charge densities. This makes them unfavourable for current-generation BEVs, as they have a much lower driving range. But LFP is holding more market share than we originally forecast, particularly in the Chinese BEV sector

LFP is a risk for nickel, and several western OEMs have made investments in LFP technology. If LFP’s share is greater than we forecast the need for new nickel capacity will be lower in the long run. There are longer-term technological risks which could displace NMC batteries, pushing a move away from nickel-intensive batteries. These technologies seem at least a decade away but could surprise to the upside.

Lessons in what technology change can mean for markets can he learned from zinc, where in the developed world demand growth has been under pressure for years due to offshoring, improvements in manufacturing technologies and the development of new alloys containing less zinc.

Metal recycling could be a significant disruptor

While demand is set to grow, particularly for copper and nickel, risks from the circular economy are growing. Secondary metal markets could become a major disruptive force in metal markets, and nowhere is this risk more acute than in China. The Chinese government has set targets for a low-carbon economy and is planning to lower CO2 emissions per unit of GDP. This could encourage a greater use of stainless scrap domestically than we are forecasting.

In the nickel market, we forecast Chinese stainless mills will increase scrap use through to 2040.

However, even by then western mills will still be using more as a ratio, and there is significant upside risk to our China projections of scrap use. A higher level of scrap use by Chinese mills could see lower demand for primary nickel units and thus increase the supply of these units for other sectors. The outlook for battery recycling could be interesting in the future and is a significant source of uncertainty.

For copper, we forecast that by 2035, scrap will meet almost 40% of Chinese copper demand. Chinese scrap consumption will grow at 6.2% CAGR (2020-2035), displacing concentrate demand on the supply side and some cathode demand on the demand side of the market. China will undoubtedly become more self-sufficient in copper raw materials, but our base case forecast too could prove too bearish.

Perhaps we should look at the lead market for some lessons. In the lead market, secondary material is dominant, but the market is still evolving. In China, rising vehicle numbers will ensure further rises in scrap volumes, which will be collected in a more efficient and regulated collection system. Smaller informal and more polluting lead recyclers have been largely removed, offset by larger, modern technology smelters chasing the scrap pool available. CRU believes that there will be further industry consolidation in the years ahead. Yet, even here in this most established of sectors, technological change will hit the market, with lithium batteries set to take share.

Opportunities and threats abound for base metals demand

Chinese stimulus measures have driven the post pandemic recovery over the past year, causing us to revise up our forecasts across base metal markets. However, Chinese growth cannot last indefinitely, and growth may already be moderating in some markets. China’s transition from a heavy industry-based economy to a lighter manufacturing and services-based economy will still take years, supporting demand from traditional sectors and for metals such as zinc. But new demand drivers will need to emerge if markets are to grow long term. For copper, future growth is almost entirely contingent on a rapid green transition. In nickel, demand from the batteries sector will power long term demand, supported by a continued expansion in the stainless sector.

The shift to EVs and renewables is coming, but there are threats, and the pace and the way these markets evolve over time is by no means certain. Increased scrap use could derail our primary demand forecasts across base metals, and thrifting, technology change and substitution are all also key risks to the demand outlook. There are also upside risks, EV penetration rates and, for copper, grid upgrades could exceed our base case forecasts.

Interested in the seminar presentations or related analysis, prices and forecasts?

Request more information about the analysis, prices, forecasts and presentations - our team will be in touch to find out how we can help you.

Get in touch with our team

General content enquiries