Previously published insights from the 'CRU explains smelting emissions’ series explain copper vs nickel emissions and copper vs aluminium emissions. Part of the series, this Insight analyses copper quality vs smelting emissions.

Already a subscriber? Go to the tool now

In November 2021, CRU released additional features (and data) within the Base Metals Emissions Analysis Tool. Smelting and refining emissions are now included as part of the full value chain emissions for both copper and nickel. This Insight provides an example of one use case for the GHG emissions data delivered by CRU models.

Copper concentrate quality drivers

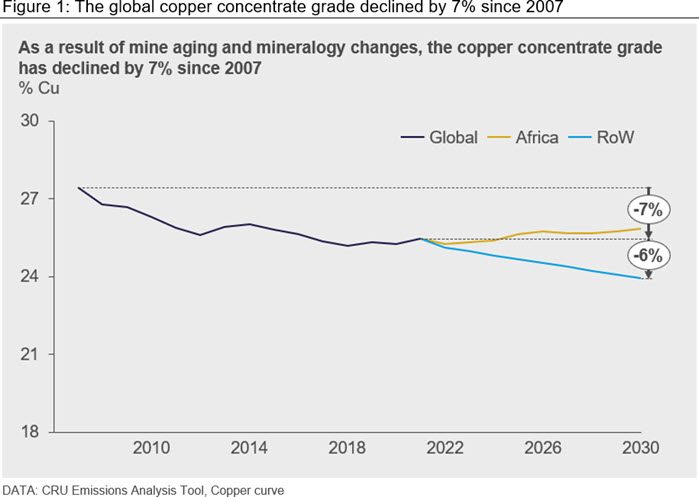

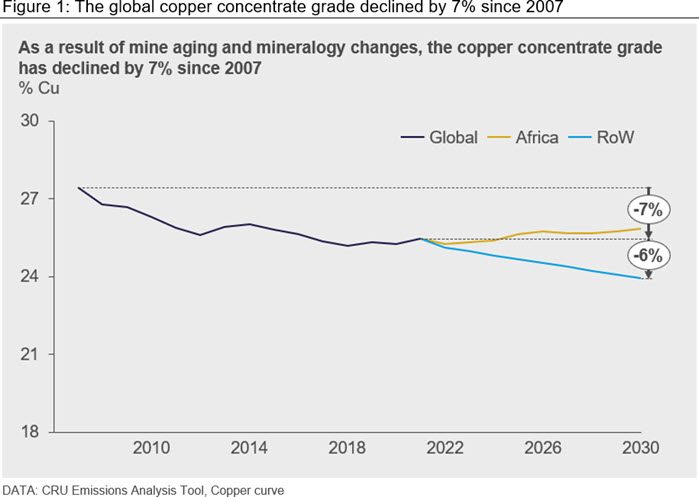

CRU data shows that the average copper concentrate grade has declined by 7% since 2007 (from ~27% to ~25% Cu content). The grade of the concentrate is primarily driven by the mineralogy of the copper deposit, as well as the success rate (recovery) of metal during beneficiation. Presence of minerals such as chalcocite and covellite can produce concentrate with a grade above 60% Cu. These secondary sulphides, however, are often found in the zones of the deposit which are close-to-surface. Chalcopyrite, being a primary sulphide, is the most common copper bearing mineral found in sulphide ores, containing up to 34.6% of copper. Given that many large open pit operations are aging, the pits become deeper and scarcer in secondary sulphides – at the same time being subjected to other complexities that can impact final copper recoveries and therefore the concentrate grade.

Interestingly, the new copper deposits in Africa are of sedimentary origin and contain significant amounts of secondary sulphides. For example, in the Kamoa mine in the DRC nearly 70% of mineralogy consist of the high copper content bornite, covellite and chalcocite. The above-mentioned mineralogy results in concentrate quality at above ~60% copper content. Finally, the copper rich minerals include significantly less iron, which drives a quality challenge at the process plant. Mines could slow down the gradual grade decline by removing a larger proportion of iron and gangue content from the concentrate. The removal does, however, mean more energy intensity to regrind as well as increased complexity of flotation – driving higher capital and operating costs.

Smelter energy intake relies on the input quality

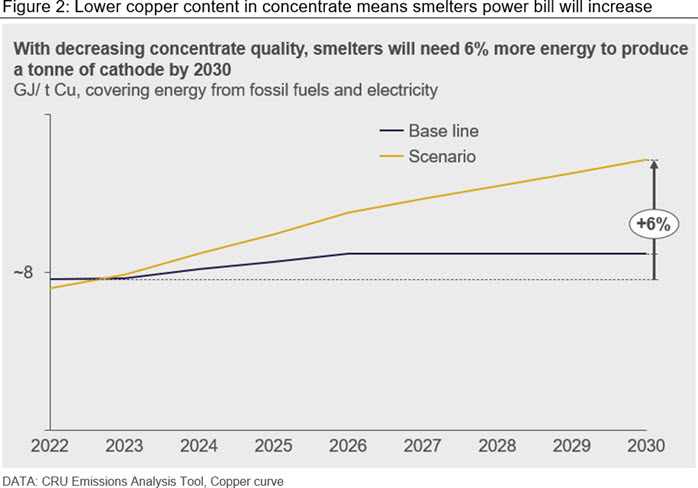

Volumes, or throughput, and quality of the raw material drive both mining but also smelting energy requirements. What has not been successfully removed prior to smelting, will either incur penalties, lower treatment charges to compensate the smelter or be removed within a regular contract. As the proportion of internationally traded African concentrates is low, we will refer to the RoW (Rest of world) concentrate grade decline, to show how smelter energy consumption may need to change.

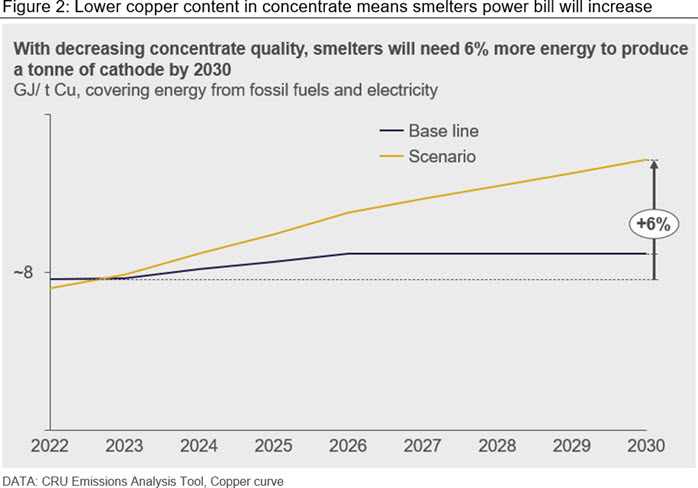

The base line shows energy intake is driven mostly by technologies used in smelting, while the scenario line shows the impact of both the technology in smelting but also a projection of concentrate grade decline. The decline means a larger throughput is needed for the same metal output, leading to higher operational costs for smelters – and a more difficult path to offset their scope 1 & 2 emissions.

Resulting emissions scenario

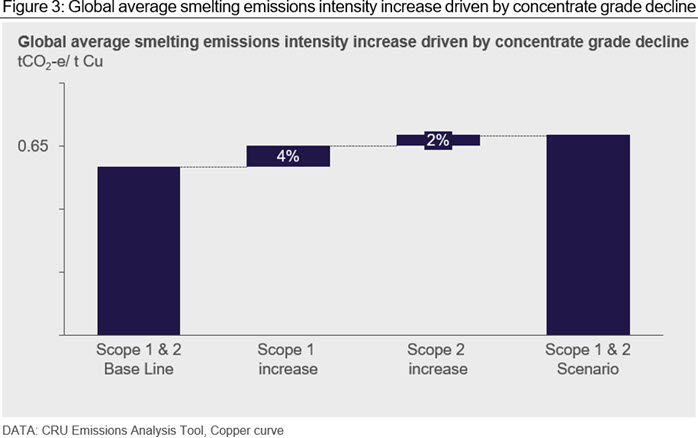

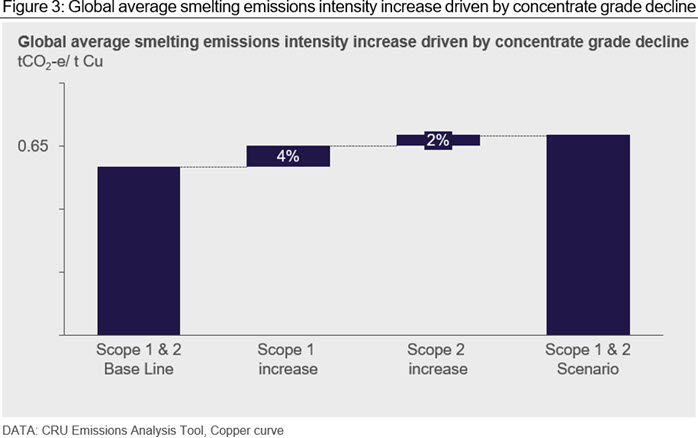

Examining copper smelter and refinery emissions data using CRU’s Emissions Analysis Tool, we are able to estimate the effect of the energy requirements on the emissions profile. The average scope 1 emissions for a copper smelter may increase by as much as 4%, while scope 2 emissions may be largely offset by country grids moving towards renewable power. The increase in greenhouse gas emissions is one of the outcomes, but we must not forget about SO emissions as well as the operational cost increases, which smelters may face in such a scenario.

While the numbers may appear small and potentially insignificant, if one considers that 22 Mt of copper will be smelted in 2030, we estimate the extra CO2-e tonnes at nearly 1 Mt. The estimate does not include additional scope 3 emissions from transporting a larger volume of concentrate to smelters, or the potentially larger costs driven by the need to blend and adjust for concentrate complexities as well as improve the economics. Moreover, the estimated decline does not incorporate the increasing impact that impurities such as arsenic, bismuth, antimony or fluorine have on concentrate recoveries. Without adequate pre-treatment (or removal), these impurities will be carried over to the smelter while simultaneously causing a lower concentrate grade from the mine, thereby further increasing the carbon bill.

To schedule an analyst guided demo of the Emissions Analysis Tool, please get in touch.

Learn more about copper emissions data and download the Emissions Analysis Tool brochure at www.crugroup.com/emissions.

Explore this topic with CRU