Author Wahome Muya

Senior Consultant View profile

Strong demand growth is expected for both the phosphate and nitrogen fertilizer markets in Vietnam, which is likely to elicit considerable interest in the Vinachem assets. Potential investors will be seeking answers to the key questions: How competitive are these assets relative to other domestic and international producers? What are the main factors that will determine their competitiveness going forward? What are the key risks surrounding these potential investments?

Growth in Vietnamese DAP and urea demand will continue to be driven by expanding rice production

Over the last few years, we have seen an extraordinary expansion in the size of the DAP market in South East Asia. Demand growth since 2010 has been the greatest of any region in the world, totalling over 1 million tonnes product. This trend is set to continue over the next five years, with projected demand growth in the region second only to South Asia, where Indian demand is recovering following policy changes earlier in the decade.

It is Vietnam that has been – and will continue to be – the driving force behind the rapid increase in South East Asian DAP demand. Vietnam is the largest DAP consumer in the region (with over 1.4 million tonnes in 2017), and is forecast to account for over half of regional growth to 2022.

Vietnam is also a significant consumer of nitrogen fertilizer, representing the 2nd largest urea market in South East Asia, and the 9th largest in the world, with nearly 2.7 million tonnes in 2017. Of the major urea-consuming countries globally, only Pakistan is expected to see faster demand growth than Vietnam over the next five years.

Why are we seeing such a rapid expansion in DAP and urea consumption in Vietnam? The answer lies in the continued growth in the country’s rice production, which in 2017 surpassed 44 million tonnes, and which now accounts for 60% of domestic phosphate and nitrogen fertilizer demand. Sustained increases in harvested land area, and rising fertilizer application rates in domestic rice fields, have helped Vietnam become the 5th largest producer of the crop globally, and the 3rd largest exporter.

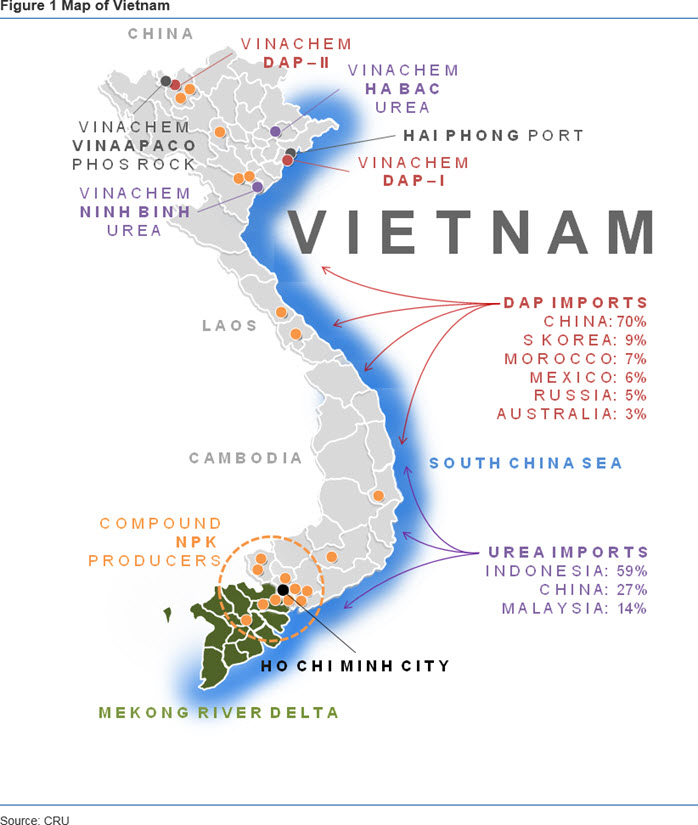

The 12 provinces of the Mekong River Delta, popularly known as the “Rice Bowl” of Vietnam, are located in the southernmost region of the country, and together account for over 50% of the country’s rice production. It is in these southern provinces that much of the country’s DAP and urea is consumed – often in the production of steam-granulated NPK fertilizers, as well as direct application by the farmers themselves.

Overall, Vietnam represents one of the largest and fastest growing markets in the world – both for DAP and urea. Such strong demand fundamentals are likely to encourage interest from a wide range of potential investors in the Vinachem production assets, all four of which are important suppliers to the domestic market.

How competitive are the Vinachem DAP assets?

Although domestic production plays an important role, Vietnam’s DAP market is still dominated by imports, which in 2017 accounted for 71% of the country’s DAP consumption. Vinachem is the sole domestic supplier of DAP in the country, with its two subsidiary companies: “DAP-Vinachem JSC”, and “DAP No. 2 – Vinachem JSC” (often referred to as “DAP-I”, and “DAP-II”). Vinachem plans to divest the entirety of its stake in both companies.

DAP-I has a production capacity of 330,000tpa, and is located in Dinh Vu, next to Hai Phong Port in the northeast of the country (as illustrated in Figure 1). Its coastal location is convenient, not only for the import of ammonia and sulphur raw materials, but also for the shipping of finished product down the Vietnamese coastline, often to Ho Chi Minh City in the South - near to the concentration of NPK plants and rice paddies.

DAP-II also has a capacity of 330,000tpa, but is located in Lao Cai, near the Chinese border in the northwest of the country. Whilst the majority of product from DAP-I is shipped to the South, product from DAP-II primarily supplies the market in Northern Vietnam.

Although imported ammonia and sulphur has to be railed ~400km to DAP-II after its arrival at Hai Phong Port, the plant is located in very close proximity to its source of phosphate rock – a mine owned by VINAAPACO, another subsidiary of Vinachem. DAP-I faces this same ~400km rail journey to source rock from the VINAAPACO mine to its coastal plant.

Vinachem plans to retain at least a 65% shareholding in VINAAPACO, despite the divestment of DAP-I and DAP-II.

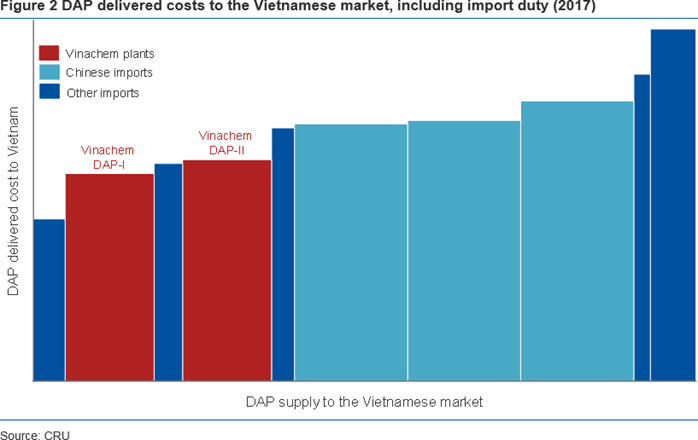

Figure 2 shows a delivered cost curve for DAP to the Vietnamese market in 2017. The curve includes estimates for the delivered cost of imports from China, Australia, Mexico, Morocco, Russia, and South Korea, as well as the site costs (ex-works) of Vinachem’s two plants.

The Vinachem DAP-I asset is situated in the 1st quartile of the curve, while DAP-II straddles the 1st and 2nd quartiles – this indicates that they currently enjoy competitive positions in their domestic market. However, it must be noted that this curve includes the additional costs associated with the DAP import duty that is levied on product from a range of countries, including Australia, Russia, South Korea, and most importantly – China. First introduced in August 2017, the DAP import duty is set at $82/t, and will run until at least March 2018, when a decision will be made on its extension. A number of countries are exempt from the duty, including Morocco and Mexico.

The introduction of the import duty has succeeded in boosting the cost competitiveness of Vinachem relative to Chinese imports, which have accounted for between 70% and 90% of imported DAP in recent years. However, it is far from certain whether this duty will be retained in the long-term, as it considerably increases the cost of production for domestic NPK producers in the country using DAP as a feedstock. The desire of the Vietnamese government to ensure the long-term sustainability of local NPK production – which accounts for 90% of domestic consumption – could mean that the DAP import duty is a temporary measure.

Another risk that potential investors would have to consider, is the possibility of increased DAP exports to the Vietnamese market from OCP and Ma’aden. Over the next five years, OCP plans to bring online over 1.7 million tonnes in additional DAP capacity, whilst Ma’aden has just commissioned its new Wa’ad Al Shamal production facility, which has a DAP capacity of 2.8 million tonnes. Vietnam could represent one of the target markets for this additional supply, as well as other fast-growing DAP import markets such as India and Pakistan.

How could increased imports from Morocco and Saudi Arabia affect the competitiveness of Vinachem’s DAP assets? To what extent does Vinachem’s competitive position rely on the continued imposition of the import duty? These are some of the key questions that any potential investor would need to take into account in its assessment of this investment opportunity.

How competitive are the Vinachem urea assets?

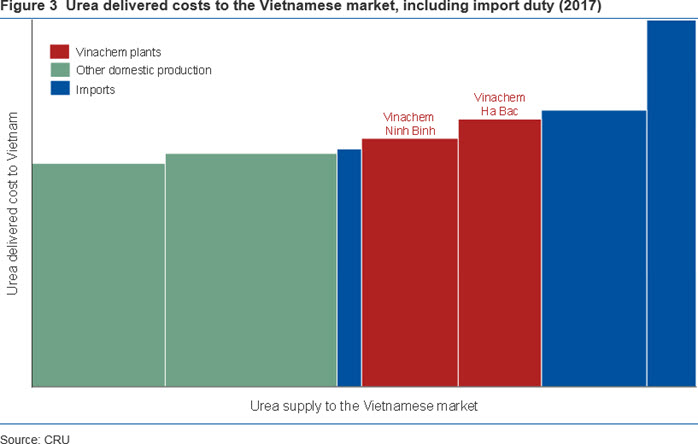

In contrast to the structure of the DAP market in Vietnam, the urea market is served predominantly by domestic production, which accounted for three quarters of consumption in 2017.

Vinachem’s urea production is carried out by its two subsidiary companies: “Ha Bac Nitrogenous Fertilizer and Chemical”, which has a production capacity of 500,000tpy, and “Ninh Bình Nitrogenous Fertilizer and Chemical”, which has a capacity of 560,000tpy. Vinachem plans to divest the entirety of its stake in both companies.

The only other urea producer in the country is PetroVietnam, which has two plants with a combined capacity of 1.6 million tonnes.

As illustrated in Figure 3, Vinachem’s urea plants occupy the 3rd quartile of the delivered cost curve, which indicates that they currently enjoy mid-level competitive positions in their domestic market. Although this curve also includes the costs associated with the urea import duty that is levied on imports from China, our research suggests that the duty amounts to approximately ~$15/t – much smaller than that of DAP. Moreover, imports from Indonesia and Malaysia, which have accounted for 65-75% of urea imports in recent years, are not subject to the duty.

Vinachem’s plants use anthracite coal as a feedstock for urea production, which is purchased from Vinacomin – the state-owned coal producer. In contrast, the plants owned by Vinachem’s domestic competitor – PetroVietnam – use natural gas as their feedstock.

Therefore, the price at which Vinachem can purchase coal, relative to the price at which PetroVietnam can purchase natural gas, will be one of the main factors that will influence the competitiveness of Vinachem’s urea assets going forward.

The government in Vietnam is under considerable pressure to allow the regulated gas price in the country to rise, in order to encourage investment in the country’s ageing gas infrastructure. For this reason, among others, our projections show PetroVietnam’s natural gas-based feedstock costs increasing at a faster rate than Vinachem’s coal-based feedstock costs over the next four years (~8% CAGR vs. ~5-6%).

With feedstock costs accounting for ~75% of the cost of producing urea in Vietnam, could we in fact see Vinachem become the most competitive supplier to its domestic market over time?

Conclusion

The prospect of strong demand growth in both the phosphate and nitrogen fertilizer markets in Vietnam is likely to provoke interest from a range of potential investors in the Vinachem assets.

To what extent does the competitive position of these assets rely on government protectionism by way of import duties? How could increased low-cost supply from international exporters affect the competitiveness of these assets going forward? How might changes in raw material prices alter their cost position relative to domestic and international competitors?

These are some of the key questions to which potential investors will be seeking answers, as they assess the risk and reward that is associated with this investment. If you would like to further explore these questions with CRU, enquire via the button below.

Explore this topic with CRU

Author Wahome Muya

Senior Consultant View profileThe Latest from CRU

Decarbonisation will reshape global steel trade flow

CRU’s Steel Long Term Market Outlook presents comprehensive analysis of global steel trade flows until 2050. Decarbonisation will play a significant role in redefining...